The Alfa Laval SB Membrane Sample Valve is a compact and reliable sanitary sampling valve designed for aseptic sampling in hygienic processing environments. It delivers accurate, contamination-free samples from tanks and pipework in industries such as brewing, dairy, food, and beverage processing. Whether sampling harvest yeast, milk, yogurt, fruit juice, or soft drinks, this membrane sample valve ensures sterility and repeatability.

*We are an official Alfa Laval distributor in Malaysia. Contact us for genuine valves, technical support, and fast delivery.

The Alfa Laval SB Membrane Sample Valve is widely utilized in hygienic processing lines where precise sampling is critical, including:

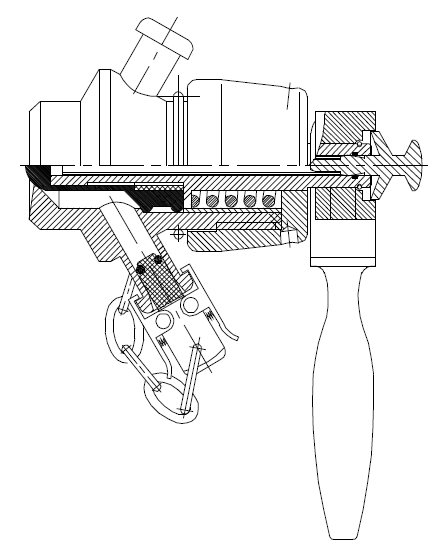

The SB Membrane Sample Valve operates using a flexible silicone membrane as a sealing plug. Opening the valve is as simple as turning the handle to allow fluid sampling, while closing seals the channel to enable sterilization between samples. The manual model can also feature a micro port, allowing sterile sampling using a hypodermic needle. A pneumatic version facilitates automated or remote sampling control, optimizing process hygiene and reducing contamination risks.

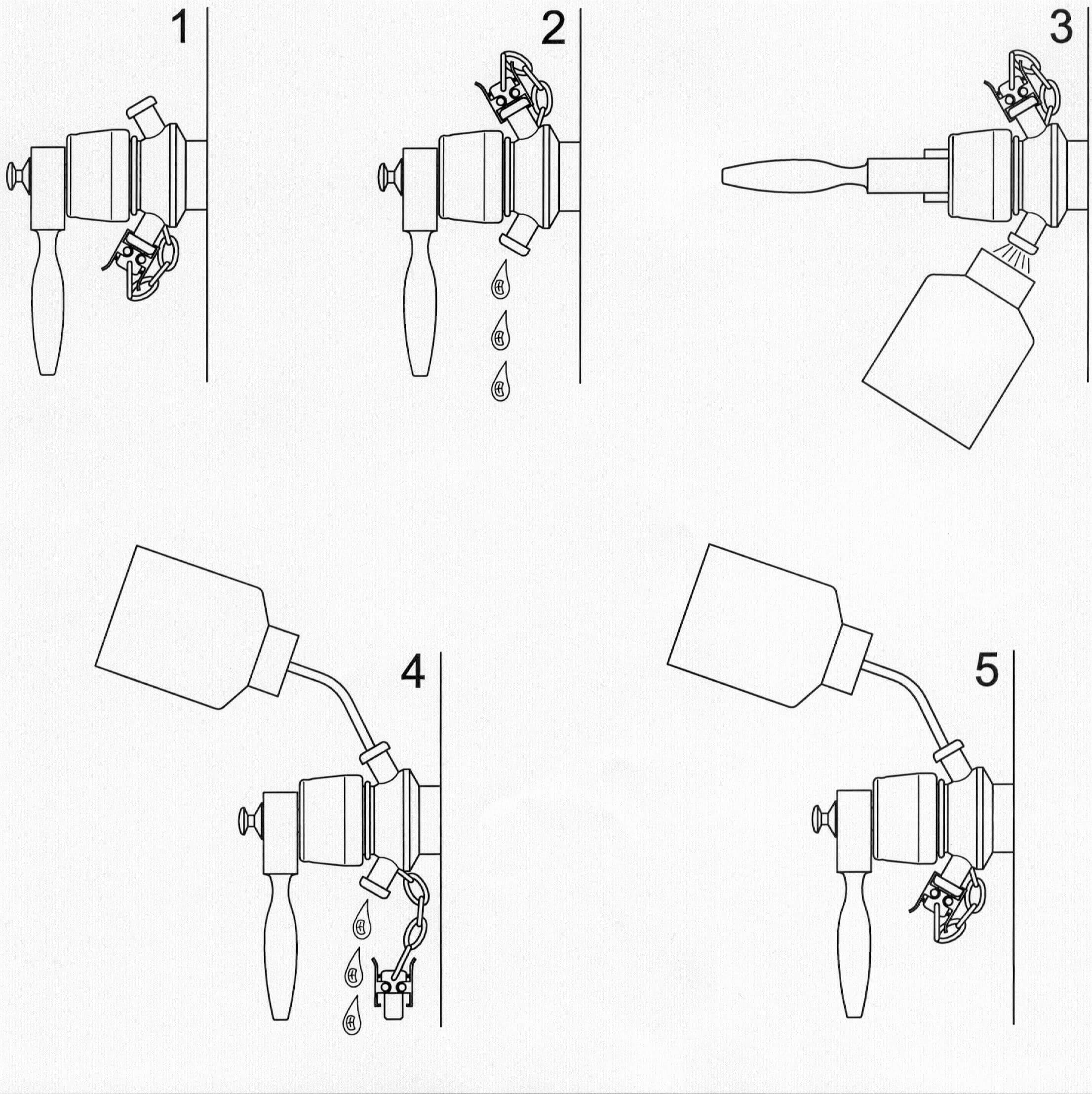

To take a sample, rotate the handle in a clockwise direction to open the valve. This retracts the membrane allowing the liquid to pass through the valve into the sample container. To close the valve for sterilization before and after taking each sample, rotate the handle in a counter-clockwise direction to channel between the valve ports is open for sterilization.

This ensures reliable, repeatable aseptic sampling results every time.

Type W – Harvest Yeast Sample Valve

Q: Is the SB Membrane Sample Valve suitable for sterile sampling?

A: Yes. It’s specifically designed for aseptic sampling in hygienic environments and supports sterilization using alcohol or steam.

Q: Can this valve be used for viscous products like yeast?

A: Absolutely. The Type W variant is optimized for harvesting and sampling viscous materials like yeast.

Q: What makes this valve different from other sampling valves?

A: Its crevice-free, weldless construction and flexible membrane provide superior hygiene and sample accuracy.

Q: Where can I buy this valve in Malaysia?

A: From us. We are an official Alfa Laval distributor in Malaysia offering genuine sampling valves and full technical support.

The membrane sample valve is used for sampling from tanks and pipework under sterile conditions. The valve is sterilized in place with alcohol or steam. Membrane sealing directly against product ensures representative sampling, giving repeatable results safe to secondary contamination.

Before opening the valve, the closing cap should be placed on upper hose piece. When handle is placed into horizontal position the required flow through the lower outlet is obtained. When handle is back into vertical position the valve is closed and the handle can be removed if required. Aseptic sampling is possible from a special valve type with micro port. By removing the red closing cap, a hypodermic needle can be inserted through a central channel into the membrane and the aseptic sampling takes place with the valve in closed position. After sampling the valve should be flushed with water or alcohol. Sterilization has to take place by means of alcohol or steam.

All types are available for manual or pneumatic operation. The two outlets are hose pieces designed as clip-on. The standard valve is equipped with one clip-on closing cap.

Product pressure: . . . . . . . . . Max. 6 bar as standard.

10 bar is available on request

Valve body: . . . . . . . . . . . . .1.4404 (AISI 316L)

Other metallic parts: . . . . . . .1.4307 (AISI 304L)

Membrane: . . . . . . . . . . . . .Silicone. EPDM on request

• Handle for operating the valve

• Assembling tool

• Membrane remover

• Proximity switch for indication of open/closed valve position

• Sampling coil with clip-on

• Isobaric hand bottling device with clip-on

• Hypodermic needle

• Silicone hose with clip-on

© 2021 ABS Engineering & Trading Sdn. Bhd. All Rights Reserved.